Infrastructure

Before we indulge in taking about Infrastructure, let us first take knowledge of what exactly is the Products that we are dealing with:

Transformers are used to transform the voltage from one level to another required level i.e. high voltage to low voltage or vice versa. Transformers used for distributing electricity at low voltages are called Distribution Transformers working at a voltage of mainly of 11KV to 0.433 KV and those having high voltage to transmit electricity from one site to another are called Power Transformers mainly of 33KV to 11KV. Distribution Transformers are used for distributing electricity in urban and rural areas, high rise buildings and industrial units.

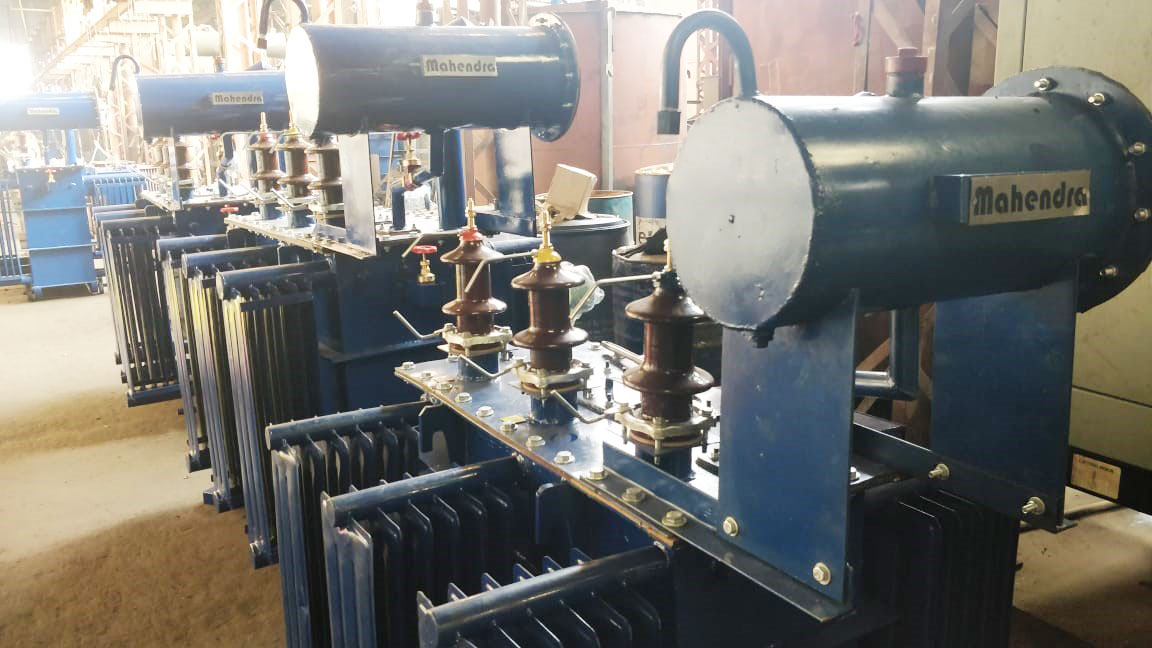

Our 'Mahendra' make transformers are being manufactured for various applications as per individual needs of customers.

'Mahendra' range of distribution transformers in 11KV/250 volts, single phase transformers is 5, 10, 16 KVA and in 11KV/433 volts three phase transformer is 16,25, 63,100,160,250 KVA in Aluminum wound windings and 160,250,400,630,1000 KVA in Copper wound windings.

'Mahendra' range of Power transformers in 33/11 KV, three phase, Copper wound are in 1600, 3000, 5000,8000,10000 KVA ratings.

Transformers have no moving parts and it works on magnetic induction principle. It has three core limbs for a three phase transformer. Each core contains 2 coils, separated from each other with insulation, one for low voltage and one for high voltage. When voltage in one coil is applied called Input voltage, it magnetizes the core due to induction effect, and then voltage is induced in the second coil, called secondary voltage or output voltage.

The output voltage depends on the turn ratio of primary and secondary windings and output is taken through LT bushing metal part connections.

It consists of two windings termed as primary and secondary windings, wound on lamination core of each limb, separated through insulations. Windings and core are rigidly clamped with yoke channels, tie rod and clamping rods. Star and Delta connections are made on LV and HV windings. The core-coil assembly is dried in the oven. The assembly is lowered in the tank filled with transformer oil. All accessories are fitted, painting is done and the complete transformer is tested as per IS-2026 as per specified routine tests.

The transformer oil serves two purposes : - One, it acts as a cooling media to dissipate heat produced in transformer due to internal losses and secondly, as insulation. The laminated core coils and tanks are fabricated as per design.